Danfoss is a global leader in providing engineering solutions and technologies.

They are committed to delivering innovative, energy-efficient, and sustainable products. The company operates in several industries, including heating, cooling, refrigeration, and industrial automation. Danfoss was developing a new frequency converter for controlling the speed of electric motors. In the design phase, simulations needed to be performed on 3D models, where the results would form the basis for the development of the inverters. However, Danfoss lacked the necessary resources to perform the simulations, and so they required assistance from a qualified engineering consulting firm.

Challenges

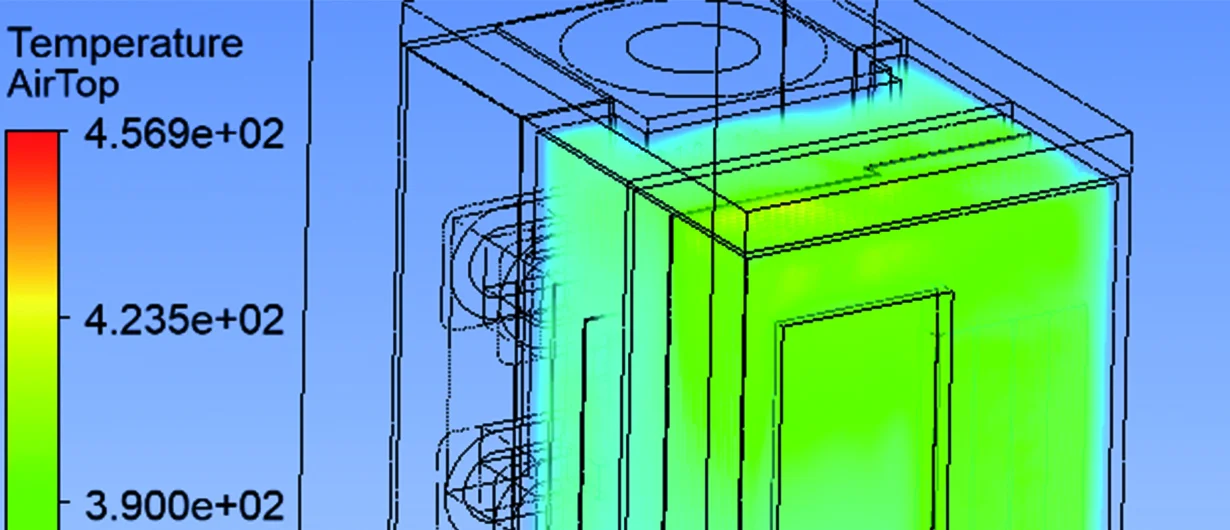

Electronics cannot withstand high temperatures, and it is crucial to ensure that installed electronics do not overheat. Simulations on the frequency converter are needed to see how fluids such as air and water behave in a chosen geometry. The geometry was simplified in a simulation model to make the devices as compact as possible. A 3D model of the entire device, including fan, heat sink, and electronics, was simulated, and various effects were placed in different places. The challenge was to pinpoint problem areas where the temperature rose significantly due to very little or no air exchange.

Solution

To solve the challenge and make the devices as compact as possible, DIS/CREADIS made a Computational Fluid Dynamics (CFD) simulation of the inverter in the design phase. The CFD simulation allowed them to see the airflow through the frequency converter and how it cooled the electronics. Based on the results from the simulations compared to results from tests carried out on prototype inverters, DIS/CREADIS proposed solutions for the design. The new initiatives subsequently proved to deliver 37 percent better cooling as a result of the simulations.

How we collaborate

>>

Danfoss needed a partner with strong skills and experience who could take overall responsibility for the simulations and provide solution proposals for the design. DIS/CREADIS provided Danfoss with a flexible simulation model that allowed them to test their ideas and avoid building too many prototypes, saving significant time. Claus E. Jørgensen, Lead Mechanical Engineer at Danfoss, said, “The simulation results and solution proposals we’ve received from DIS/CREADIS have given us very important knowledge, and we are now in the process of testing the presented solution proposals.“

How we collaborate

<<

Danfoss needed a partner with strong skills and experience who could take overall responsibility for the simulations and provide solution proposals for the design. DIS/CREADIS provided Danfoss with a flexible simulation model that allowed them to test their ideas and avoid building too many prototypes, saving significant time. Claus E. Jørgensen, Lead Mechanical Engineer at Danfoss, said, “The simulation results and solution proposals we’ve received from DIS/CREADIS have given us very important knowledge, and we are now in the process of testing the presented solution proposals.“

Are you interested in learning more about DIS/CREADIS?

Enter your information in the form and we will contact you shortly.